Author:Yang, L., Ye, Z. S., Lee, C. G., Yang, S. F., & Peng, R.

Abstract

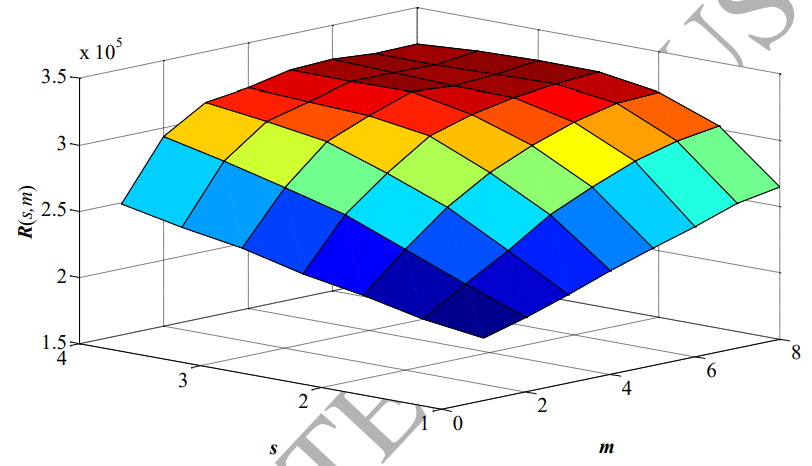

This paper investigates a novel two-phase preventive maintenance policy for a single-component system with an objective of maximizing the revenue generated by the performance-based contracting (PBC). The system undergoes a defective state before failure, and produces signal hinting the condition. The maintenance policy consists of two phases: imperfect maintenance phase followed by postponed replacement phase. In the imperfect maintenance phase, inspection is performed to reveal the defective state, leading to a possible repair. Both the inspection and the repair are imperfect. In the postponed replacement phase, preventive replacement is performed during the upcoming scheduled maintenance window, before which no inspection or repair is executed. The expected net revenue under PBC is maximized via the joint optimization of the inspection interval, number of inspection and preventive replacement interval. We apply the model to a case from a steel converter plant, and the results show that our proposed maintenance policy outperforms some existing maintenance policies in terms of the net revenue.

Keywords:Maintenance; delay time; imperfect repair; postponed replacement; performance-based contract.